Automated transportation, special sieving, weighing and packaging unit

It is a complete automated unit suitable for all processing industries of cereals, animal foods etc., which consists of:

1. An appropriate inclined feeding screw conveyor

2. A specially designed sieving arrangement of incoming materials

3. A feeding hopper of the automatic weighing-packaging machine type "A-100", supported on metallic bases.

4. An automatic weighing machine type "A-100" for weighing and packaging of open mouth bags.

5. And an automatic sewing machine type "SR-2000”.

Automated reception, transportation, sieving, weighing, packaging and sewing line

It is a totally ergonomic process line of different materials (such as flour, cotton,cereals etc.), which includes:

1. A feeding hopper of the material

2. An inclined feeding screw conveyor, equipped with an appropriate sieving arrangement. The sieving residues are collecting in a suitable resistance bag is adjusted in the outlet spout of the sieving arrangement.

3. A feeding hopper of the automatic weighing-packaging machine type "A-100" supported on metallic bases.

4. An automatic weighing machine type "A-100" for weighing and packaging in open mouth bags.

5. and an automatic sewing macnine type "SK-1500"

Automated mixing, weighing, receiving, transportation and packaging line

It consists of:

1. A vertical material's mixing, weighing and reception unit, which is based in a special support platform and includes:

1a) An horizontal mixer, equipped with a weighing system.

1b) And a special reception hopper of final material, linked with a horizontal evacuation screw conveyor.

The unit is supplied with raw materials via air pneumatic conveying systems, screw conveyors etc.

2. A vertical bucket elevator.

3. An automatic weighing machine type "DIAS-300" for weighting and packaging in valve bags.

4. An inclined hydraulic conveyor with a horizontal part.

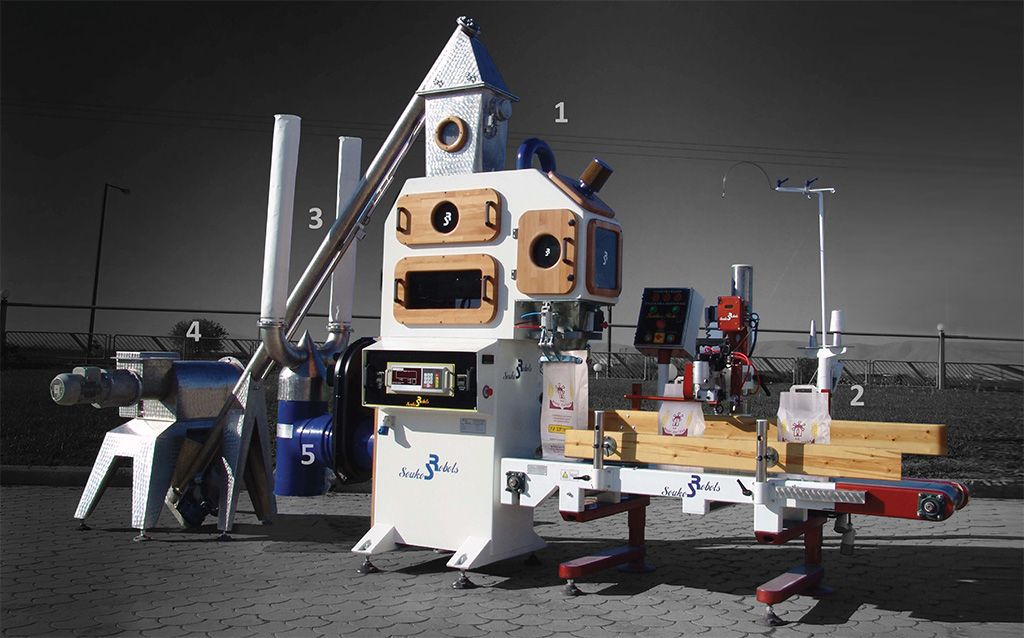

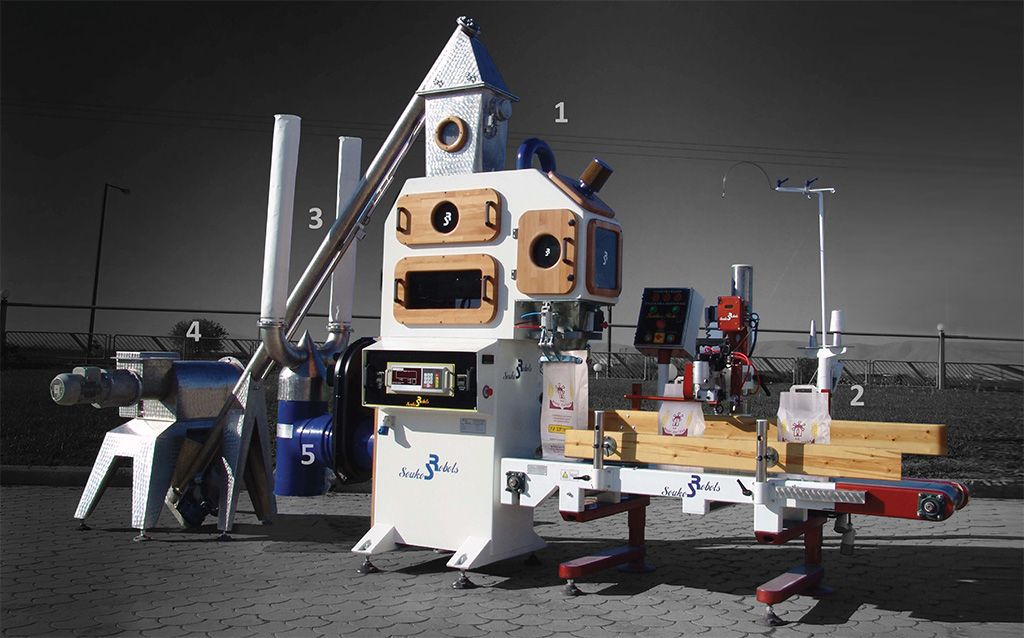

Automated weighing-packaging and sewing line

It is an automated weighing - packaging and sewing line of products, mainly types of flour, in small-sized open mouth bags. The line is formed by:

1. An automatic weighing machine type "CRONOS" for weighing and packaging in small-sized open mouth bags.

2. And an automatic sewing machine type "SR-1500".

For the smooth flow and operation of the line, in the automatic weighing machine type "CRONOS", different machines are adjusted, such as:

3. Inclined feeding screw conveyor.

4. Treatment and cleaning system for floury products.

5. Dust suction system, ensuring ideal working conditions for the operator as well as for the surrounding's hygiene.

Automated mixing,weighing transportation and packaging line

It consists of:

1. A horizontal stainless steel mixer, equipped with a weighing system, which is based in a suitable support platform.

2. An automatic weighing-packaging machine type "A-100", for weighing and packaging in open mouth bags.

Automated weighing-packaging, sewing and transportation line,for large productivity output

It is a complete automated unit, which is designed for the smooth weighing, packaging, sewing and transportation of different materials in every type of open mouth bags. The system thanks to its modular design can be adjusted and correspond to the different production and packaging line requirements.

It consists of:

1. An automatic rotating weighing-packaging machine type "CAROUSEL M-5" with five (5) spouts, for weighting and packaging in open mouth bags.

2. Automatic sewing machine type "SR-2000"

3. A hydraulic telescopic conveyor belt type "TG-114-H"

Mobile modular reception, transportation, weighting and packaging unit

It is a high-technology unit of machines, which is placed inside an appropriate container in order to enable its transportation in every desirable material's loading or storing place.

The innovation of the mobile unit lies in the fact that the machine's sub-parts are shortened-lengthened outside/inside of the container in an automatic way.

Main parts:

1. Raw materials reception hopper.

2. Two inclined screw conveyors for safe and quick transportation of raw materials from the reception hopper in the automatic weighing and packaging machine.

3. Automatic weighing and packaging machinejype "HEF container.

4.Automatic sewing machine type "SR- 2000".

In order to provide you with the best online experience this website uses cookies.

By using our website, you agree to our use of cookies.

Learn more

I agree

Cookies are small files containing information that are sent to your browser from a website that you visit, facilitating the website to hold information in relation to your visit, such as your preferred language and other settings. This can facilitate your next visit and make the site more useful to you. Cookies are important. Without these, the use of the web would be a much more complex experience.

We use cookies for many reasons. We use them, for example, to remember your preferences of Safe Search, to offer relevant ads, to estimate the number of visitors to a page, to enable you to subscribe to our services and to protect your data.